|

Highly resistant.

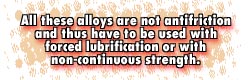

Mean antifriction properties and high corrosion resistance.

Excellent wear resistance. Remarkable fatigue strength.

Forgeable.

Achieved according to the regulations of the table UNI 4855 "Casting

copper alloys as ingots and castings - Generalities and tests"

VALUES REFERRED TO FORGES PIECES

| Designation |

Composition |

Unitary ultimate tensile stress

R

[kgf/mm2] |

Elongation

A

[%] |

Brinell hardness

HB

[kgf/mm2] |

Supply |

DURAN E

DURAN E/Ni

DURAN E/2 |

Cu/Zn/Mn

Cu/Zn/Mn/Ni

Cu/Zn/Mn/Ni |

40÷50

55÷65

55÷65 |

10÷20

8÷12

8÷12 |

130÷160

160÷180

160÷180 |

Sand casting

Chill casting

Forged |

The trademarks of bronzes "CM" "DURAN" "MAC"

assure the unchangingness of mechanical and metallurgical characteristics

in the castings we produce.

DURAN E - DURAN E/Ni - DURAN E/2

Gears; ring gears; scrolls; nut screws; shafts and rods of pumps; high

pressure valves; housings of ball bearings; sliding blocks for rolling

mill adapters; various parts.

|